- Marketing & Sales Representation, Procurement & Supplies

- Energy and Power Services

- Mechanical Services

- Integrated Plant Maintenance Services

- Project Management including Major and Minor Shutdowns

- Pipeline & Process Services

- Safehouse Pressurized Habitat

- Specialist Oilfield Services

- Integrated Logistics Solutions and Local Support Services

- Consultancy Services

- Digital Transformation Services

- Water Solutions

- Renewables and Energy Efficiency Solutions

- Back to Home

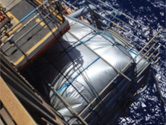

SAFEHOUSE Pressurized Habitat

In partnership with SAFEHOUSE habitats, global leader in the provision of engineered safety solutions for hazardous atmospheres, Tendrill are pleased to offer a fully certified pressurized habitat that allows hot work to take place in hazardous zone 1 and 2 areas. SAFEHOUSE habitats manage and mitigate the risks associated with conducting hot work in potentially hazardous areas, without the need for a production shut-down.

PROVIDING FULLY CERTIFIED TECHNOLOGY THAT:

- Reduces risk and improves process safety

- Optimizes cost

- Extends asset life and improves integrity

- Maintains production targets

PERSONNEL AND SUPPORT

- Internal training and competence program for habitat installation and operation

- Dedicated local project team and QHSE Management from our operational base

- Onsite surveys available by competent habitat technicians and supervisors

SAFEHOUSE habitats utilize pressurization with automatic gas detection and shut down systems to provide a safe working environment and ensure hot work can be completed safely in potentially hazardous environments.

HOT WORK WITH SAFEHOUSE HABITATS

SAFEHOUSE habitats can be used to carry out any type of hot work, such as welding, cutting or grinding, in a hazardous area. This is achieved by:

- Containment

- Pressurization

- Modular construction

- Air extraction

COMPLEMENTARY EQUIPMENT AVAILABLE

SAFEHOUSE habitats can be used with a range of complementary equipment including:

- Air conditioning module – SafeCool (creates cool working environment)

- Gas sensing module

- Multi-sensing module

- Pressure differential module

- Remote gas sensor

- Welding control module

-

SafeCool Air-Conditioning Unit (ACU)

SafeCool Air-Conditioning Unit (ACU)

-

Gas Sensing Module (GSM)

Gas Sensing Module (GSM)

-

Multi-Sensing Module (MSM)

Multi-Sensing Module (MSM)

-

Pressure Differential Module (PDM)

Pressure Differential Module (PDM)

-

Remote Gas Sensor (RGS)

Remote Gas Sensor (RGS)

-

Welding Control Module (WCM)

Welding Control Module (WCM)